-

Posts

824 -

Joined

-

Last visited

-

Days Won

4 -

Feedback

0%

Content Type

Forums

Events

Store

Articles

Posts posted by xtriggerman

-

-

-

I don't think you taking it apart with a mallet had anything to do with it. That pin takes a recoil hit from the bolt body on every shot. Being a hardened part, constant battering can over time make the metal crystalline. When that happens, you get what you have there, a clean snap. They are great pistols indeed. Back in the 80's I sold a 5.5 bull barrels one to a friend of mine who was an exceptionally good shot. We used to hang bulls eye targets on a single finishing nail. I had worked the trigger on that Ruger for him and once he got the hang of it, I watched him drop 3 targets off the board by taking the nail out with one shot, off hand, open sights, 30 feet! God, I wish I could have done that with my High Standard... or with anything for that matter. Some folks just got it like that!

-

1

1

-

-

Back when I had a full service shop, I saw out of the box atrocities come out of Colt, Ruger, Beretta, Remington and S&W just off the top of my not so good memory. I bought a S&W 645 when they first came out and it was a flyer meca. So when I gave it the once over, I found that some how (that I cant understand) the chamber was visibly way off center! On one side the chamber wall was dam near in line with the top of the lands while the opposite side funneled deep into the bore. The only way this could happen is they don't use a piloted chamber reamer and the barrel was spinning terribly off center when they bored the chamber. I called S&W on it and to their credit, I had a brand new barrel out of a mail box in a few days with no sending the old one back. The worst case was Beretta on a M21 22 auto that came threw with a gouged chamber wall so bad that it would only eject half the mag at best. You could see the gouge and the fired casings clearly shown a bulge. I ended up doing mail tag with them. The first 2 times they replaced nearly all the parts in the gun including the grips! the third time back they gave me a new gun for the customer. I guess they had no one in CS there at Accocakee MD who knew how to replace a barrel on one of those tip up 21's. A couple years earlier I had the same gouged chamber issue on a Beretta Target M76 22 and they replaced the barrel first time threw. When I ran the 1911A1 assembly line at Auto Ordnance I learned what relation quality control had over pre paid gun orders..... the stories I could tell you all about that is somewhat amusing looking back now!

Good luck with the 60, normally CS has a no holds bared from making it better than it would have been out of the box. At least that's how things used to be. I remember a heavy barrel Browning Buck Mark I sold to a guy had a very rough bore so when I got it back with a new "good" barrel, they gave me 2 new mags with it for free.

-

The single action is virtually a knife edge sear engagement. The slightest burr or blunt trigger sear edge will compromise the sear groove lock up. I'm guessing its all but a 2 minute job to reseat the sear contact points. They should fast track that for you. Those are nice little carry guns... still on my bucket list.

-

Personaly I would take the Remington. The 760 is the hight of the non auto fast follow up shot rifles. They are durable to the point where they will put up with a lot of internal dirt. The only thing to look for on the Rem is make sure the extractor is in good working order. Rusty/sticky chambers will raise hell with the extractors by loosening up their rivet. If they eject nice and clean on firing, they are more than likely OK. The only old 110 that I would partly consider would be a detachable clip feed. Otherwise they are not bad but the 760 is a kick a** hunting rig. And you cant go wrong with the 06 cal.

-

On 2/5/2017 at 8:55 AM, Ronald_55 said:

Nice! Sounds like you are a guy that should just start designing and building from scratch.

Improving on an existing design is a gratifying thing. Yesterday, I worked on a little Spanish pocket 25 that had ejection issues. With some milling on the ejection port, that puppy is now spiting spent shells out 12 feet away rather than 2 feet away.....some times.

-

1

1

-

-

This is one of my "what if" guns that I am nearly done with but it actually shoots fine as is right now. About a year or more ago I picked up this Iver model 67-S Viking 2.75" 38 S&W at a GS. It was cheap enough because it had a bad trigger recoil spring in it. My intension for it was to load snake shot loads for it for around the house. Then one day I saw that 3" I.J. Supershot barrel and frame parts for sale on Ebay. I thought what if I could put the older supershot 22 barrel set onto the 38 frame? I had to try it since there were a few pluses in the final franken gun. The old world Supershot sealed 8 top break guns were beautifully machined with tapered light weight barrels and an auto eject feature. But by 1947 Iver had to cheapen the guns to stay competitive with the H&R 999. Once the Supershot turned into the model 66, The barrel became a bulky casting and they ditched the auto eject feature for a finger ejection rod. The 66 did have some important improvements such as a fixed firing pin with transfer bar, a nice wide spur hammer and a much needed larger trigger & trigger guard. So basically, I love the old Supershot top end but the newer 66 had the far better lower frame. So I set about mating the 2 together. I ended up getting a nice 6" supershot barrel from Numrich but found the forcing cone was off center. So I made a cutter up to correct that and found I have to cut new cylinder notches in the Supershot cylinder since the frame lug of the 67 center fire frame didn't line up. But that was fine since I could now match each cylinder bore with barrel bore using a brass alignment pin I made up. Milling each of the 8 cylinder notches threw the frame lug hole assured me a more accurate gun in the end. The newer & nicer rear sight/frame latch fit perfectly on the old barrel frame and of course the center fire FP bushing was removed, welded shut and remachined for a spring loaded FP of my own design. The frame did need a bit of weld to get a tight lock up also. I intend to color case harden the frame once I make up a crucible for a kiln I have. That will toughen the lock up to where it should be.

Below you see one of the weak areas of the IJ design. The trigger rebound spring is not a good one. I tried to install a new Numrich spring in the gun and flat out couldn't get it to work worth a s***. you see it inside the trigger guard here. So I revised the design with duel spring arms that are seated into holes drilled into the forward potion of the guard as pictured. The new springs have a longer arc of bend to them and with about a dozen careful thinnings, I have a nice reliable and lighter trigger pull over that stock joke of a spring they sent me. Also you can see I put the cylinder lock up lug spring mid body on the lug for a far more reliable and solid cylinder lock.

All that remains to be done is build up the front sight with some weld to match the higher rear sight and kiln color the frame and bingo, I have that old world top break I always wanted yet with modern full cylinder safe carry AND auto eject. No one in their "sensible" mind would ever go about a job like this so don't ask what it would cost..... never said I was sane when it comes to old guns :?

-

6

6

-

-

I also hope and pray your wife will come threw. I would like to make a suggestion. Get her on this product called PH Balancer. The woman that developed this formula had fatal brain cancer until she put it in remission with this. As a Biochemist for Merck, she REALLY knows what cancer is all about. My wife (has issues) takes it as her Dr. was very impressed with the ingrediance. Blessings be upon your wife.

-

-

A long time ago I had a huge mulberry tree that was about 30 yards from my door. It would draw them in during the day. At the time, I kept a Ithaca 22 semi auto loaded with CCI stingers for the chucks behind the house. So when I saw the coyote, that's what he got. First one went down dead after about a 20 yard run, second one ran all the way to a tree line about 100 yards before he dropped dead. Neither of the dogs had exit wounds. The area wasn't the best for anything more power full. 22mag would be a better choice.

-

1

1

-

-

2 hours ago, OngoingFreedom said:

Chiappa .44 Magnum takedown "Skinner Bush Pilot Kit"

http://gunsmagazine.com/the-skinner-bush-pilot-kit/

Sent from my iPad using TapatalkThat is the coolest thing I have seen in a long time!

-

Back in October I once again got an 03FFL. Aside from a lack of funds, I really don't have anything in the must have bucket list column. Living dangerously, Iv been known to browse the GB C&R listings on occasion (sorta like having unprotected sex). Well, who can resist the dream world of a Luger holding at $500? I clicked on it. Now every one knows that Luger will close at something that wont be anywhere near the 5 bones it had 5 days out from the gavel. But I clicked on it anyway. Here is the specimen in question....

This particular Luger is a 1906 model that was produced as a 5000 gun contract for the Brazilian Gov. This one is more than likely made in 1908 or early 1909. Its all original & matching numbers with a mint bore. This condition is rather about as good as it gets since these guns saw hard service. Now all that is more or less bla bla bla to me since I never wanted anything too nice to shoot and I figured Id run into a rough mix master someday to play with but here is the kicker. Back in Feb of 88 when I was graduating from the state Corrections academy, I watched them call us up front for our badge presentation one by one. All the guys were getting these brand new 14-1500 numbered bright gold badges, then they called me up there and they hand me this badge in a new case but it didn't look like all the others, mine had the bright gold rubbed off all the high spots and the rest was more like a dull silver gold and the number on it was 1259. Looking at it, I thought now that's a coincidence... if you add the first two numbers together, you get my birth day and the 59 is my birth year! That Badge served me well over the 25+ years I had it. In all that time, my knees and elbows never had to try n dent a concrete floor! Being a might bit superstitious, now you know..... the rest of the story. Closing at $1150 + 25 to ship C&R direct, I think I got a hell of a deal.-

8

8

-

-

4 hours ago, peejman said:

You could combine the tap idea with heat/cold. Get the tap to grab and heat the outside of the chamber with a propane torch. Once it's hot, spray the inside of the case with some aerosol freeze spray and it should come right out.

Your right, that should work pretty good. The thing is, you never know if you have to go that far with it. In this case, better to go the extra work or you might end up with just the back end of brass. There are only about 3 instances a brass casing will lose its head. Excessive head space, a reload that's been reloaded way too many times, a reload that's just loaded way to hot, a chamber that has rust pitted chamber walls can make all those instances far more possible in semi autos. Extra precaution is never a bad thing!

-

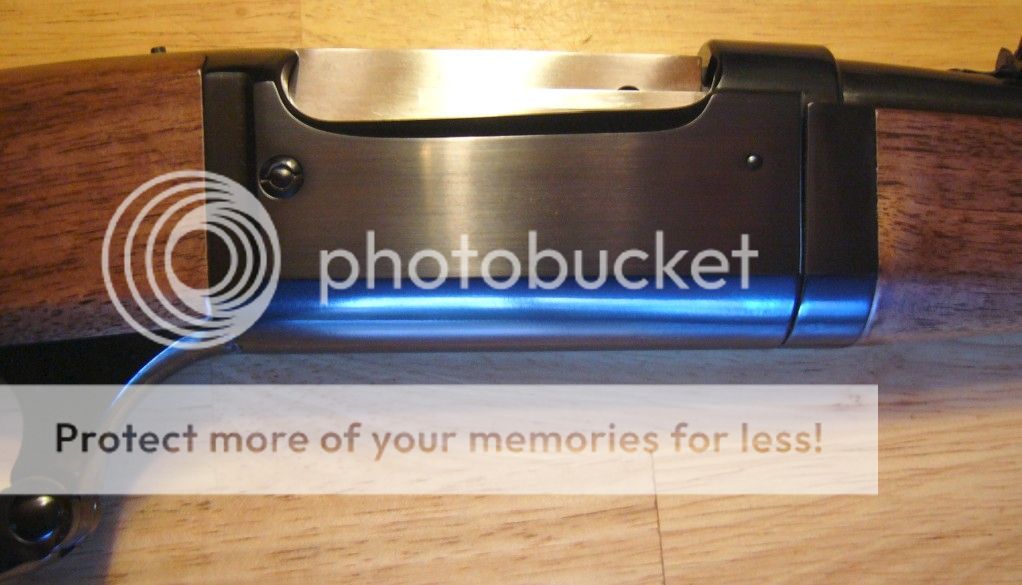

Clearly, your Dad is great gunsmith himself. I like the custom touch of extended splinter forend and stretched receiver wood panels. Very tastefully done with the custom checkered panels..... a real keeper to pass down! Your lucky you have a Dad like that. My Dad didn't want to have any guns. He was a Lt. in the Germany Wehrmacht during WWll and wounded 3 times on the Russian front. I guess all that messed him up some.....

-

1

1

-

-

16 minutes ago, gregintenn said:

It shoots fine, but it now appears the extractor is awol..........more parts from gunpartscorp!

Such is my luck with a pig in a poke.

I really enjoy fooling with historic pieces such as this however. This ont is chambered in 38-40, and has a 24" octagon barrel and a cresent buttplate. Had the previous owners taken care of it properly, I likely would have never had the opportunity to hold this rifle.

That Marlin is a real Gem. Anything that's tapered (unlike todays Henry's) octagon with crescent steel butt & a breach loader instantly rises to the top of the drool list! Weird how that is..... I used to work for George Numrich at Auto Ordnance which was across the parking lot from what is Thegunpartscorp of today. you should have seen what was called the "break down room". 8 foot high racks filled with handguns of all sorts in every kind of disrepair and stacks upon stacks of rifles every where. The only time George would put someone to work salvaging parts in there for the parts bins is when the orders slowed down. They all ways had parts pickers walking off with antique & current goodies out of there in their lunch bags.

I see you like 99's, I was at a Gander mountain yesterday and they had a basic 99E in 300 Sav their for sale. Nice shape but nothing special with colored hard wood & press checkering. Burned my hands on the price tag of $1049 !!! What the hell are they thinking? Years ago I restored a 1899 303 TD for a friend of mine. It was spray painted to stop some bad pitting going on and the stock was cracked nearly in 2. A real basket case. I put new wood on it with a crescent butt & complete reblue. Heres how it came out....

Jimmy was in shock when I handed it back to him. He likes shinny stuff.....

-

5

5

-

-

Certainly a great way to make that fix. Just a word of caution, all ways measure the leading OD of the cartridge against the tap OD to be used making absolutely no question that you wont cut all the way threw the brass & into the chamber wall. That could make for one very bad day if only the back side of brass comes out and leaves tap cuts in the chamber wall. Easy does it is the key here!

-

1

1

-

-

I read somewhere that the run of USA made guns were flooding back to CS for quite a lot of issues. Maybe that did them in.

-

5 hours ago, Polock said:

THANK YOU SO MUCH!!! I'm going to look this weekend; now that you've confirmed that its a light-duty spring that basically just needs to fit, I am more confident in finding one. Is there any chance you either have, or would be willing, to send me pictures of the breakdown of the slide and firing pin assembly? I found a schematic, but it doesn't look exactly like my gun and I'm wondering if I may be missing another piece. Again, I GREATLY APPRECIATE all your help and if this is too much to ask, I certainly understand. I don't really know where else to turn, and seeing that you have the same gun that I now have and you obviously know what you're doing....well, thought I'd ask. I don't know the proper protocol for asking thru this WEBsite and I don't want to do anything wrong, so here is my EMAIL and if "no" is the answer, I certainly understand. THANK YOU! Mark J (Kcolop@GMAIL.COM)

OK your welcome. Here is Numrich's schematic. I can walk you threw the fix right here. http://www.gunpartscorp.com/Manufacturers/MarlinGlenfield-33379/Rifles-37333/47-38988.htm

The Marlin 22 cal pump has the fewest number of action parts than any other 22 pump action firearm making it a synch for most any one to do a take down of the action. To accomplish this, Open the action just slightly and cock the hammer. Unscrew the large take down screw on the right side of the action. Once its loose, bump the action lightly right to the rear of the take down screw head. This will pop the action apart. lay the left side of the action on a table and examine how the bolt and bolt lock (#37) move and lock into battery in the action. Once that is understood, Lift off the pump action bar off the lock pivot pin and just push the pump handle forward out of the way. Lift out the bolt and bolt lock together. Remove the lock from the bolt and simply lift out the firing pin. The firing pin spring is # 28 on the schematic but its a poor picture. You will see the hole where the spring sits just below the FP channel cut in the top of the bolt. Its at the very rear of the bolt where the hammer hits the pin. The spring is 9/16ths long and 1/8th in diameter. Once you have located a rather soft light duty spring, cut it to length and pinch the cut ends inward slightly with good plyers. Assemble the FP onto the spring and check its action. The firing pin should have a nice n easy smooth spring loaded forward and back tension. If this is so, reassemble in reverse manner. You need to under stand the firing pin will not alow the bolt lock to fold up into the bolt unless the firing pin is pushed all the way in as in "hammer down" position. As for using the forum for a personal message, just put your cursor on the user name at top left and then on "message" in the new pop up box. If you have no luck finding a spring, use that PM box to give me your mailing address and I should be able to find a spring that will work.

One more hint. When putting the action bar back onto the lock pivot pin for re assembly, be sure the spring that is the shell stop #9 is fit into the action bar edge cut channel. If that engaging nub of that spring is not fit in the cut of the action arm, you wont get the action halfs to tighten up flush with each other.

-

In this article the guy explains exactly how the wholesalers of extra large ammo consignment purchases get shafted with sanction rules along with indirect manufacturers. Its an interesting read.

-

1

1

-

-

2 hours ago, Mike in East TN said:

ITAR is for import / export. I know there was something in obama's wish list that would have made general gunsmithing under that heading. BATFE agent who interviewed me and inspected the site said nothing about ITAR.

Hi Mike,

I also originaly was going to go back into the gunsmithing business when I retired here 2 years ago. I had everything done with the state, even the "franchise tax" registration to pay taxes. Only the FFL was to be applied for, then I read all about the new ITAR language. Here you can read what these Lawyers seem to think they have a cash cow nitch in ITAR litigation for serving gunsmiths. Note the outrageous fines for violation! Needless to say, I have learned from the locals to fly under the Fed radar like so many "private" gun show tables. We looked at Rodgersville 3 years ago also but nothing jumped out at us. Im setting up a Kiln for color case hardening if you ever get in a jam for some colors. Ridiculous what they get for that on the net these days!

https://blog.princelaw.com/2016/07/25/ddtc-issues-guidance-on-itar-registration/

-

Mechanically, wheel guns are all ways more prone to velocity variance due to the nature of the beast. The most prevalent reason is the barrel cylinder gap. If you have a good set of feeler gauges, measure the gap at each cylinder mouth with the hammer at rest. Even the smallest difference will give you what you have. you should see .005 +/- .001 for a good gap. Once you find the gauge with a slight resistance, hopefully that same resistance will be found on each cylinder mouth. The loser will be your low vels. Cylinder concentricity with the barrel bore is the second item that can effect vels by a tad also aside from being the cause of flyers as most all ready know. One other area that gets overlooked is the forcing cone that makes up for non true to the bore cylinders. You would be surprised to know how many wheel guns have out of center bore cones and are within factory specs. Just the slightest out of center cone will try to force rifling into only one side of the bullet way before rifling is available on the opposite side of the cone. This to is a pressure consideration. Those 3 things are the foundation of performance center built wheel guns.

-

1

1

-

-

12 minutes ago, Ronald_55 said:

Academy Sports has some 200 round boxes for FMJ Monarch on sale for $34.99. Free shipping on orders over $25. That comes out to 17.5 cents BEFORE tax. Maybe not quite as good, but if you are close to a store you can probably just pick it up.

http://www.academy.com/shop/pdp/monarch-9mm-luger-115-grain-pistol-ammunition#repChildCatid=3821051

Since Academy is in TN, the sales tax kicks it up to 19 cents /rnd. I'v fired a lot of Wolf 9 and never had a bad round so for the money I think those 72 round Sumoi drums will get the springs wound up!

-

1

1

-

-

Just put in an order for 2K rds. With the commerce going bad with the Russians this may be the last time you will see .18 cents a round shipped.

http://www.the-armory.com/shopsite_sc/store/html/9mm_ammo.html

-

13 hours ago, Polock said:

Excellent info and THANK YOU FOR YOUR TIME AND KNOWLEDGE!! Yeah, the gun is in pretty good shape...can't say I'd ever fire it 'cause there is a certain comfort knowing my grandpa was the last to pull the trigger; haven't decided yet, but may build a display case and hang it on my wall. But, I would like to have it fire-worthy in case I someday change my mind. Is there any chance you'd know of any place I could find a replacement firing pin spring? I checked Numrich and GunPartsCorp without any luck. Not sure if there is a suitable substitution possible. Again, ANY suggestions or info is VERY much appreciated! MarkJ (polock)

Any light duty spring that will fit that diameter hole can be fit to work. If you don't have any luck finding one give me a PM w/ address and I'll make one up for you n put it in an envelope.

-

1

1

-

A Season For Smiths

in Handguns

Posted

Garufa,

That grip used to be the stock target grip but I wanted something that fit my fingers and a rounded bottom left side for palming it in tight. I used to shoot that 29 off hand pretty good with full house loads. But then the grey hair & bifocals got in the way.